|

|

Fugitive coal dust emissions control to help with your clean coal projects....

Fugitive dust emissions from coal occur during material loading, unloading, transferring, stockpiling and other material handling procedures. Utility companies, power plants, steel mills and coal mine facilities are required to comply with regulations as they relate to water and air quality, as well as the impact on aquatic and human health.

Sediment, as a result of runoff or windblown particles, deposits into drains, ditches or lakes and can seriously endanger plant and aquatic life. Erosion control is much more effective than sediment control. By stopping erosion before it becomes sediment, you can avoid costly clean-up and environmental effects from even occurring.

|

|

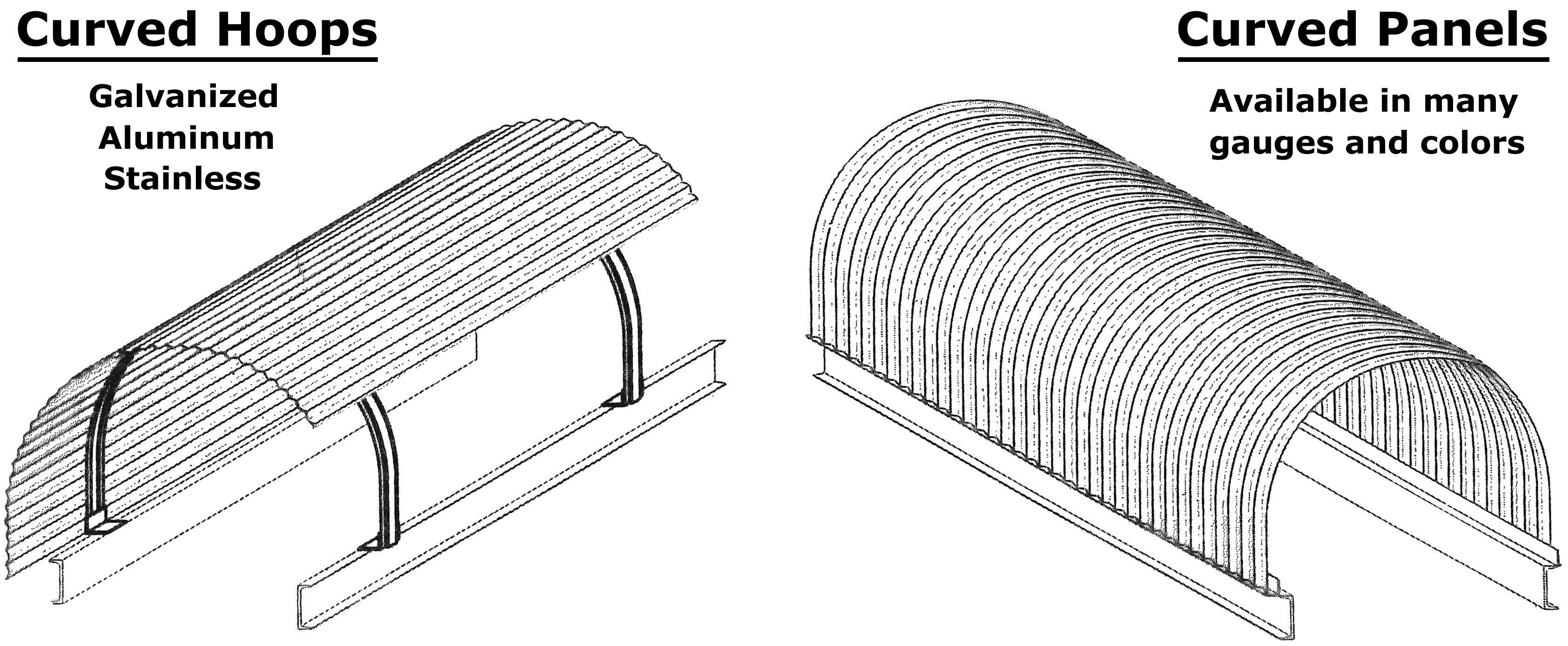

When you need curved for your Conveyor Cover System....

Flexospans curving mill can create a multitude of shapes. We offer radius curve with a tangent, without a tangent, or with a double tangent. Radius-curved panels can be installed over purlins or conveyor cover hoops. Curving by Flexospan results in a continuously smooth, un-crimped curve. It is available to radii as tight as four feet.

Mining facilities....

Day-in and day-out, mining facilities wage a constant battle against fugitive dust. With todays ever-tightening operating budgets and environmental regulations, you need to be able to control dust efficiently.

Avoiding accidents as well as the negative community relations that uncontrolled dust can cause is a must.

Just as dust can be a nuisance, ice and snow freezing on your conveyors can also cause concern in winter weather conditions.

Covering conveyor systems will improve the environment while safety also increases.

|

Metal Roofing and Siding Panels, Steel Purlins & Girts, Self-Storage and Industrial Metal Buildings

Metal Roofing and Siding Panels, Steel Purlins & Girts, Self-Storage and Industrial Metal Buildings